Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

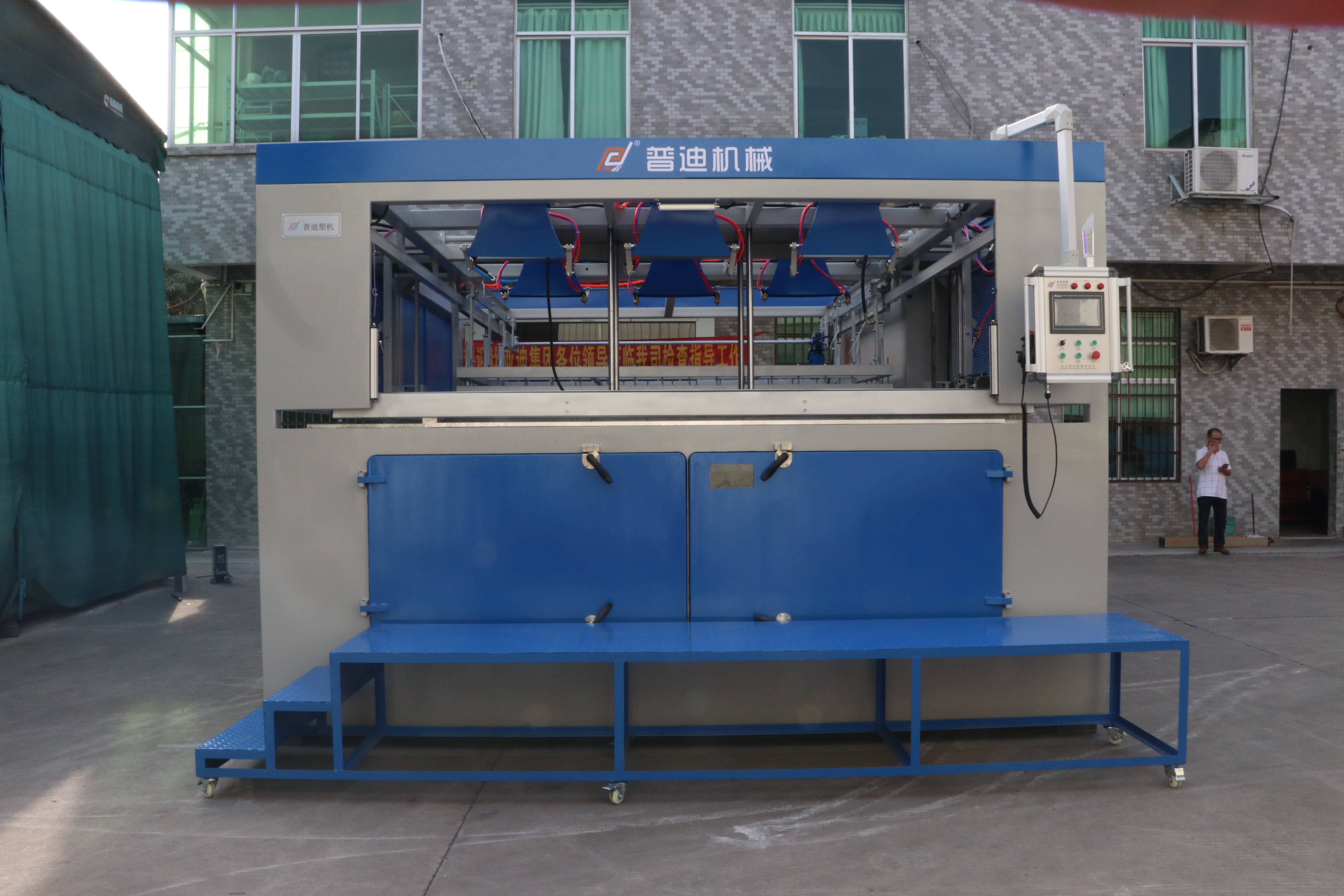

The hydrophobic tray thermoforming machine is designed with high-tech and exquisite craftsmanship. It can also monitor itself to know its condition from each part, then to make good reply to protect them and make them work in good condition. It’s energy-saving and quiet, can adjust multi-stage pressure to make the trays in good technology according to the tray special manufacture characteristics.

Automatic:

The machine is designed to perform the entire thermoforming process automatically, without the need for manual intervention. The machine is equipped with advanced technology and features. The machine automatically feeds the plastic material into the forming area, and heats the plastic material to the required temperature for thermoforming. Besides, it can intelligently trim the excess plastic material from the formed tray.

Exquisite Technology:

The heating part is made of stainless steel heating stick with anti-oxidization and shockproof. It can increase the heat with a steady but fast level to make a good preparation to make trays. The temperature sensor can be based on the environment temperature to give a feedback to the temperature controller, then it can accurately control the temperature. The exquisite technology is in high technology, make you feel safe and release your hands.

Product Parameter:

|

Maximum Wellhead Size |

2600mm*1600mm |

|

Forming Depth |

500 mm |

|

Applicable Material Thickness |

1-10mm |

|

Main Switch |

three-phase five-wire 380V±15V, 50Hz |

|

Heating Power |

Upper Furnace: 128kw; Lower Furnace: 128kw; |

|

Total Power |

280kw (subject to actual conditions, normal use is between 50-70%) |

|

Mold Forming Method |

Concave-convex molding (one-shot molding) |

|

Electric Furnace Power |

Frequency Conversion Motor Drive |

|

Die Power |

Servo Motor (both upper and lower mold tables are driven by servo) |

|

Cooling Form |

Powerful Fan |

|

Heating Unit |

fast medium-wave infrared heating tube, analog voltage regulation and temperature control |

|

Vacuum State |

Matching Large or Small Secondary Vacuum |

|

Upper Frame Structure |

It can be adjusted arbitrarily according to the different mold sizes |

|

Sheet Conveying |

Manual Placement |

|

Product Demoulding and Pick-up |

Air Pressure Blowback Demoulding |

|

Other Functions |

Bubble Blowing, Anti-sag, Large and Small Vacuum |

|

Adaptable Processing Materials |

PP. PC. PE. PVC. ABS. PS and other thermoplastic sheets |

|

Machine Dimension |

3800mm*4600mm*3200mm (excluding the upper mold) |

FAQ:

---One machine can be also accepted.

---About 15-60 days, the detailed time needs your detailed information.

---We are factory.

---Yes, we can support. If you have detailed picture or information, you can leave it to us, once we see it, we will reply to you as far as possible.

---The best is to support drawings.